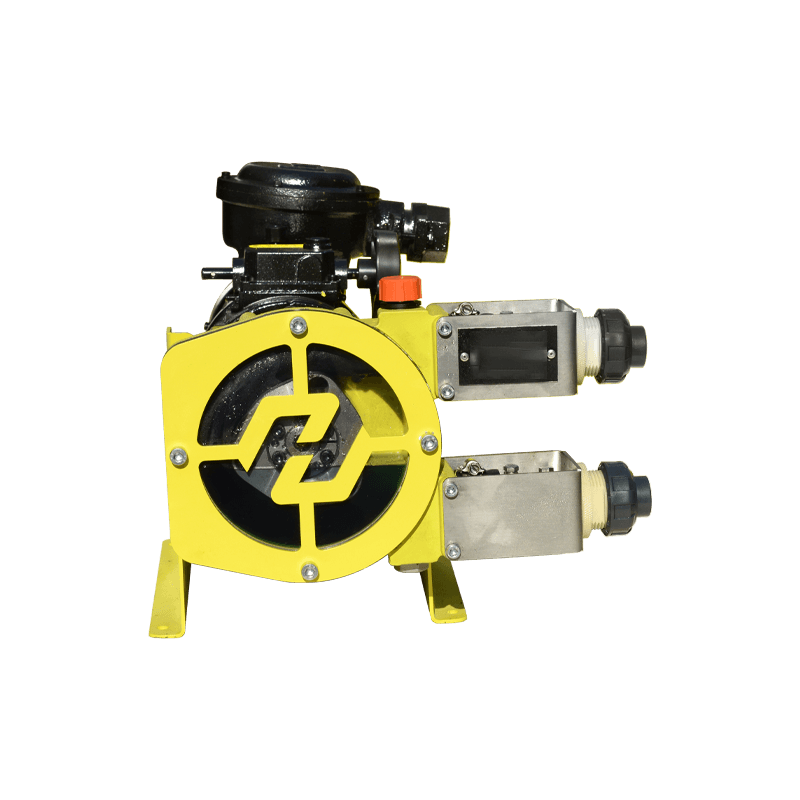

Hose pump

Leading products Global sales network

>Rolling extrusion, Soak in lubricating oil, Extending hose life

>IOT intelligence, real-time online condition monitoring, preventive hose replacement

>Stainless steel pump, resistant to harsh corrosion environment, far superior to laboratory peristaltic pump

>Compact structure, small installation space, light weight, far better than the construction hose pump

>Accurate and repeatable dosing and metering.

Industry requires repeatable pump control for accurate dosing. Many traditional positive displacement pumps have varying flow rates, resulting in scrapped product and increased costs. HIGHPUMP are accurate up to ±1% across their total speed range, with the additional benefit of process control capabilities which allows easy installation. Less waste means increased profits.

>Longer life and greater reliability.

Pump failure cannot be tolerated. HIGHPUMP have no seals, valves, diaphragms, glands or immersed rotors to leak, clog or replace. Abrasive, corrosive and aggressive liquids are handled with ease because the fluid stays within the hose and never comes into contact with moving parts of the pump. The HP series range is designed and manufactured for heavy duty industrial use, and advanced elastomer technology ensures accurate and repeatable performance that truly outperforms all other pumps.

>Self-priming and continuous dry running.

It is not always possible to position a pump in the ideal location and often self-priming and dry- running performance is required. These conditions can cause wear in conventional pumps, resulting in loss of flow and premature failure. HIGHPUMP can self-prime up to 9.8 meters and run dry indefinitely.

>Lowest cost of ownership and quick and easy maintenance.

Leakage, clogging or blockage of conventional positive displacement pumps which incorporate seals, valves, lobes, rotors or vanes can be a regular occurrence and expensive to rectify. HIGHPUMP contain the fluid hose, requiring only one component to be changed, which means that maintenance costs are considerably lower than other pump types. Increased plant productivity and lower repair costs means pump payback is over months rather than years.

Unit(L/H)

| Model | 20RPM | 40RPM | 60RPM | 80RPM | 100RPM | 120RPM |

| HP09 | 26 | 52 | 78 | 104 | 130 | 156 |

| HP13 | 54 | 108 | 162 | 216 | 270 | 324 |

| HP17 | 139 | 278 | 417 | 556 | 695 | 834 |

| HP25 | 410 | 820 | 1230 | 1640 | 2050 | 2460 |

| HP30 | 600 | 1200 | 1800 | 2400 | 3000 | 3600 |

| HP45 | 2300 | 4600 | 6900 | 9200 | 11500 |

13800 |

Company name

Whatsapp number

*Phone No.

*Share your ideas

info@hankunchina.com

+86-15810403962

+86-15810403962

+86-15810403962

+86-(0)10-63260308